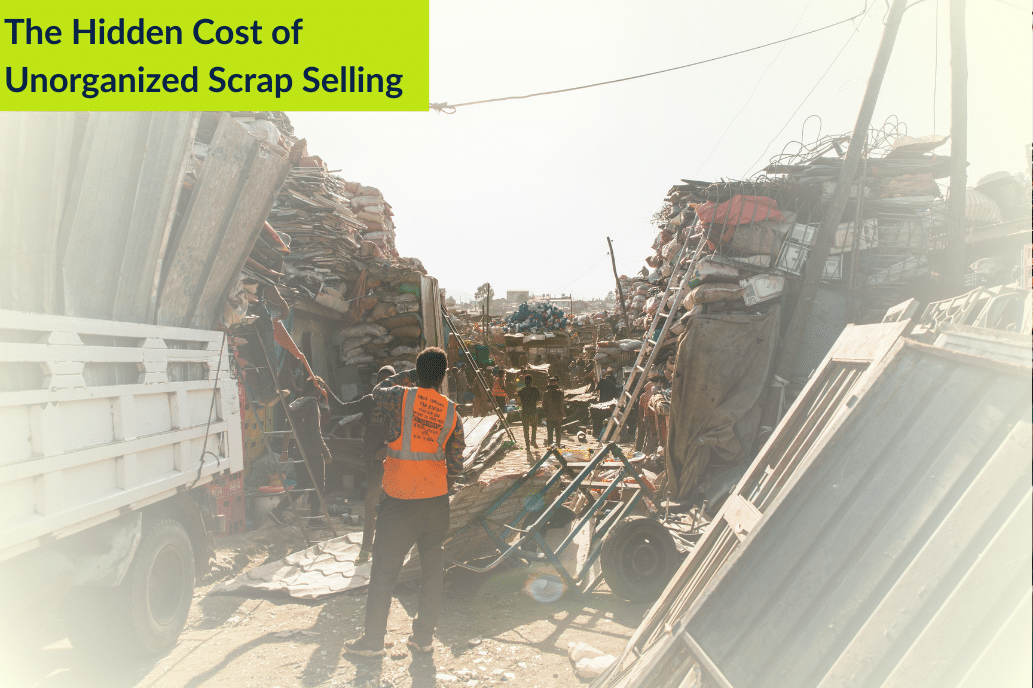

Unorganized scrap selling rarely shows up on balance sheets, yet its cost quietly compounds over time. For manufacturing companies, scrap is often managed informally, handled by local buyers, negotiated over calls, recorded manually, and moved without digital trails. While this approach feels convenient, it carries financial, operational, and compliance consequences that are far from obvious.

The first hidden cost is price erosion. When scrap is sold without standard categorization or multiple buyer visibility, pricing depends entirely on the buyer’s assessment. Mixed scrap, inconsistent weighing, and lack of documentation give buyers leverage. Over time, manufacturers accept lower rates as “normal,” unaware of how much value is being left on the table.

The second cost is operational inefficiency. Unscheduled pickups, delayed clearances, and repeated follow-ups consume time and space. Scrap yards overflow. Safety risks increase. Production teams get distracted. None of this appears as a direct expense, yet it affects productivity daily.

Then comes dependency risk. Many plants rely on the same buyers for years. If that buyer exits, delays payments, or fails compliance checks, the entire scrap operation stalls. This dependency weakens negotiation power and limits flexibility during market fluctuations.

Compliance risk is the most underestimated cost. With EPR requirements expanding, manufacturers are increasingly expected to demonstrate traceability of waste movement. Informal scrap selling rarely provides GPS records, pickup proof, or structured documentation. During audits, these gaps translate into corrective actions, delayed approvals, or reputational damage.

Unorganized selling also weakens sustainability narratives. ESG goals rely on data: how much waste is generated, where it goes, how much is recycled. Without digital records, sustainability teams rely on assumptions rather than evidence.

So what changes when scrap selling becomes organized?

It begins with digitization. A digital scrap register brings consistency. Every batch is logged, categorized, and measured. This alone improves buyer confidence and pricing accuracy.

Next is access. Listing scrap on an organized platform exposes sellers to multiple verified buyers. Price discovery improves. Deal closures speed up. Local dependency reduces without disrupting existing relationships.

Movement transparency closes another gap. GPS tracking and photo-based pickup documentation create accountability. Disputes reduce. Audit readiness improves. Finance teams gain cleaner records.

Analytics connects the dots. Manufacturers can finally see trends, which plants generate more scrap, which categories underperform, where value leaks occur. Decisions move from reactive to strategic.

Scrapeco is built for industries that want to move away from unorganized scrap selling without taking unnecessary risks. By removing entry barriers, the platform allows companies to test a structured, transparent scrap workflow. From digital listings and verified buyers to tracked pickups and EPR-aligned data all through one unified system. It’s a shift from informal handling to informed control, introduced at the industry’s own pace.

The real cost of unorganized scrap selling is not just lost revenue. It has lost control.

Manufacturers that transition early gain clarity, resilience, and stronger compliance footing. Those that delay will eventually be forced to change under pressure, not choice.

The question worth reflecting on is:

How long can scrap remain “unorganized” before it starts costing more than it earns?

Compliance adds another layer of risk. As EPR obligations expand and audits become stricter, scrap without traceability becomes a liability. Missing movement records, lack of documentation, and informal handovers create gaps that cost money later, either in penalties, corrective actions, or lost business trust.

So how do industries fix this?

The starting point is structure, not negotiation. Value improves when scrap selling becomes a process, not an afterthought.

Digitally maintaining a scrap register changes everything. When scrap is logged by type, quantity, and batch, sellers gain clarity. Buyers respond differently when material details are transparent. Negotiations become factual, not speculative.

The next shift is moving away from dependency on local middlemen. Access to multiple verified buyers across regions improves price discovery. When buyers compete, value rises naturally. This is where online scrap selling platforms play a critical role. Listing scrap digitally allows industries to reach beyond their immediate geography without losing control.

Verified buyers matter. Selling to uncertified or unknown parties may seem convenient, but it introduces long-term risk. Vendor verification reduces disputes, improves payment reliability, and supports compliance needs. Searching for old scrap buyers near me should no longer mean choosing the nearest option, it should mean choosing the most reliable one.

Logistics transparency is equally important. Digital pickup scheduling, GPS movement tracking, and photo-based pickup proof reduce delays and disagreements. When scrap moves faster, cash cycles shorten. Faster closures directly improve realized value.

Analytics is where industries unlock long-term gains. By studying scrap generation trends and value recovery patterns, plants can identify:

- Which scrap categories deliver the highest returns

- Where segregation can improve pricing

- How operational changes impact waste value

Platforms like Scrapeco are designed around these exact gaps. Through free registration and a 90-day feature trial, industries can list scrap, access verified buyers, schedule pickups, track movement, and analyze performance; without lock-ins or hidden charges. The intent is simple: let sellers experience structured selling before any commercial commitment.

Globally, scrap markets are becoming more data-driven. India is now catching up. Industries that treat scrap as a managed resource rather than operational waste will consistently outperform those that don’t.

The question every plant head should ask is:

If scrap is generating revenue anyway, why not stop losing value while selling it?